| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : KTS

Model Number : Cone Pointed End

Certification : ISO9001:2008

Place of Origin : SICHUAN,CHINA

MOQ : 100 Piece/Pieces

Price : $1-10/Piece

Payment Terms : L/C, T/T, Western Union

Supply Ability : 250000 Piece/Pieces per Month

Delivery Time : 7-30 Day

Packaging Details : Standard export cartons

Type : SM Carbide Burs

Name : CONE SHAPE CARBIDE BURRS

Material : TUNGSTEN CARBIDE

Grade : YG6X YG6 YG8 YG8X

Features : Anti rust\high strength

Cut : SINGLE/DOUBLE/ALUMINUM

HARDNESS : HRC50-60/HARC92.5

LOGO : CUSTOMIZED

Certificate : ISO9001:2008

Type of Cut : DOUBLE/FINE/SINGLE/DIMOND/ALU CUT

SM Carbide Burs - Cone Pointed End

| Product name : | Tungsten Carbide Rotary Files | shank diamter : | 3mm/ 6mm |

| Brand : | KTS | Packing : | Set Packing |

| Head hardness : | HRA 89-92.5 | speed of tool : | 15000-45000Turn/min |

| Material : | Tungsten Carbide | Certificate : | ISO9001:2008 |

Product Main Characteristics:

1. It can be used to process various metals (including various quenched steels) and non-metallic materials (such as marble, jade and bone), and the hardness of the processed workpiece is less than HRC 70;

2. In most work, handle is used to replace small grinding wheel, without dust pollution;

3. It has good processing quality and high smoothness, and can be used for high-precision processing of various mold cavities;

4. It has a long service life, and its durability is ten times that of high-speed steel tools and more than 200 times that of small grinding wheels;

5. Easy to master and operate, safe and reliable. It can reduce labor intensity and improve working conditions;

6. The economic benefit is high, and the comprehensive process cost can be reduced by 10 times. Generally, carbide burrs are driven by manual electric or pneumatic tools (also used for machine tools). Generally, the rotating speed of electric or pneumatic tools is between 6000 and 50000 rpm.

Technical date

| S.N. | MATERIAL |

| 1a | Steel |

| 1b | Hard steels |

| 2 | Stainless steel |

| 3 | Cast iron |

| 4 | Titanium |

| 5 | Nickel |

| 6 | Copper/Copper alloys |

| 7 | Aluminum |

| 8 | Plastics |

| 9 | Cement |

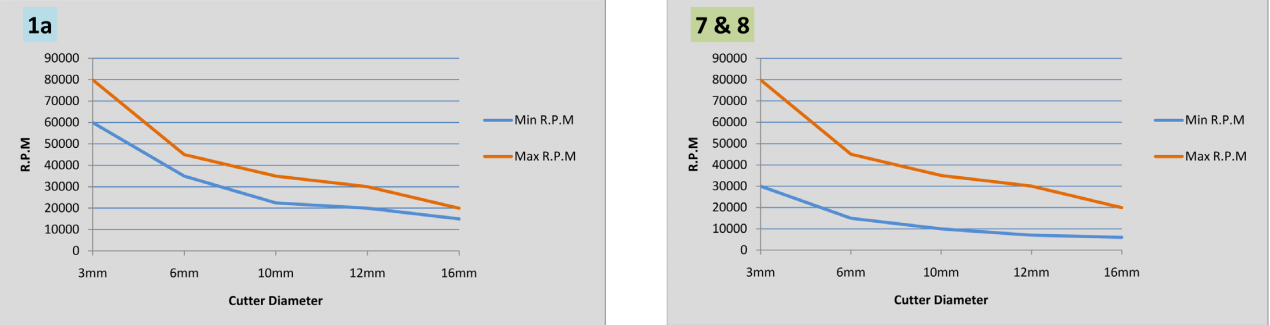

Guide to running speeds

mat nr. MAX RPM | 3mm/0.123" 90,000 | 6mm/0.250" 50,000 | 10mm/0.375" 40,000 | 12mm/0.500" 35,000 | 16mm/0.625' 25,000 |

| 1a | 60,000-80,000 | 35,000-45,000 | 22,500-35,000 | 20,000-30,000 | 15,000-20,000 |

| 1b | 60,000-80,000 | 30,000-45,000 | 19,000-30,000 | 15,000-22,500 | 12,000-18,000 |

| 2 | 60,000-80,000 | 30,000-45,000 | 19,000-30,000 | 15,000-22,500 | 12,000-18,000 |

| 3 | 45,000-80,000 | 22,500-45,000 | 15,000-35,000 | 11,000-30,000 | 9,000-20,000 |

| 4 | 60,000-80,000 | 30,000-45,000 | 19,000-30,000 | 15,000-22,500 | 12,000-18,000 |

| 5 | 60,000-80,000 | 30,000-45,000 | 19,000-30,000 | 15,000-22,500 | 12,000-18,000 |

| 6 | 45,000-80,000 | 22,500-45,000 | 15,000-35,000 | 11,000-30,000 | 3,000-20,000 |

| 7 | 30,000-80,000 | 15,000-45,000 | 10,000-35,000 | 7,000-30,000 | 6,000-20,000 |

| 8 | 30,000-80,000 | 15,000-45,000 | 10,000-35,000 | 7,000-30,000 | 6,000-20,000 |

| 9 | 60,000-80,000 | 30,000-45,000 | 19,000-30,000 | 15,000-22,500 | 12,000-18,000 |

|

|

High Strength SM Cone Carbide Burr HRC50 To 60 Cone Pointed End Images |